Configure-to-Order (CTO) manufacturers create or select products by using combinations of validated features, options, values, or attributes. Configuration rules ensure product integrity. Final configurations create unique manufacturing bills of material, routings, costs, and prices for customer quotes and sales orders.

Exceed Customer Expectations with Rules-Based

Product Configuration and Personalization

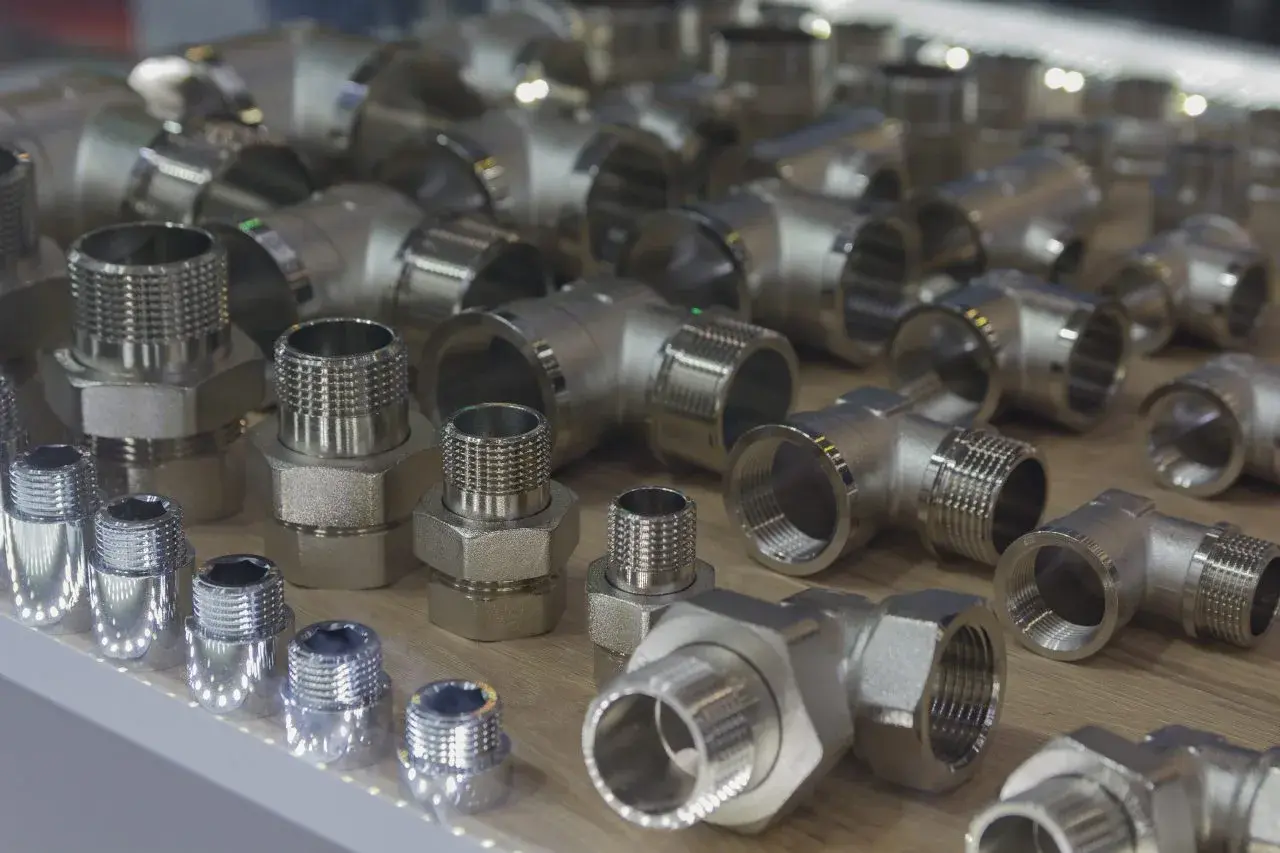

Many products are available in varied configurations. Architectural products like doors, windows, and cabinets have different dimensions and are manufactured using varied materials and finishes. High end bicycles are built to order with many options for seat posts, handlebars, braking systems, wheels, and other optional components.

Configuration is common in other manufacturing industries, including automotive products, electronics, home goods and furnishings, machinery and equipment, and instruments and medical devices.

Companies with limited product variation may use matrix items to define finished goods when few configuration options are available. Conversely, other manufacturers require rules-based product configurators to manage interdependencies and formulas for complex products. The result is thousands of possible variations based on a variety of options.

Product configuration is becoming more mainstream as consumers and business customers demand personalized products. Commerce storefronts give people self-service power to build the exact products they need without assistance from the manufacturer. Known today as configure-price-quote (CPQ), product configuration

has evolved to include parametric visualization where users can see product variations as they select or deselect options and attributes.

This industry brief explains configure-to-order manufacturing with an overview of ERP technologies and features. Discover how leading manufacturers thrive with a modern ERP platform designed for configure-to-order manufacturing.